Some Of Plasma Cutting Toronto

Wiki Article

Durma Press Brakes Toronto - An Overview

Table of ContentsPlasma Cutting Toronto for BeginnersSee This Report about Plasma Cutting TorontoNot known Details About Durma Fiber Laser The Only Guide for Laser Cutting TorontoLaser Cutting Toronto - TruthsDurma Fiber Laser - An OverviewThe Best Strategy To Use For Durma Press Brakes TorontoOur Durma Equipment Toronto PDFs

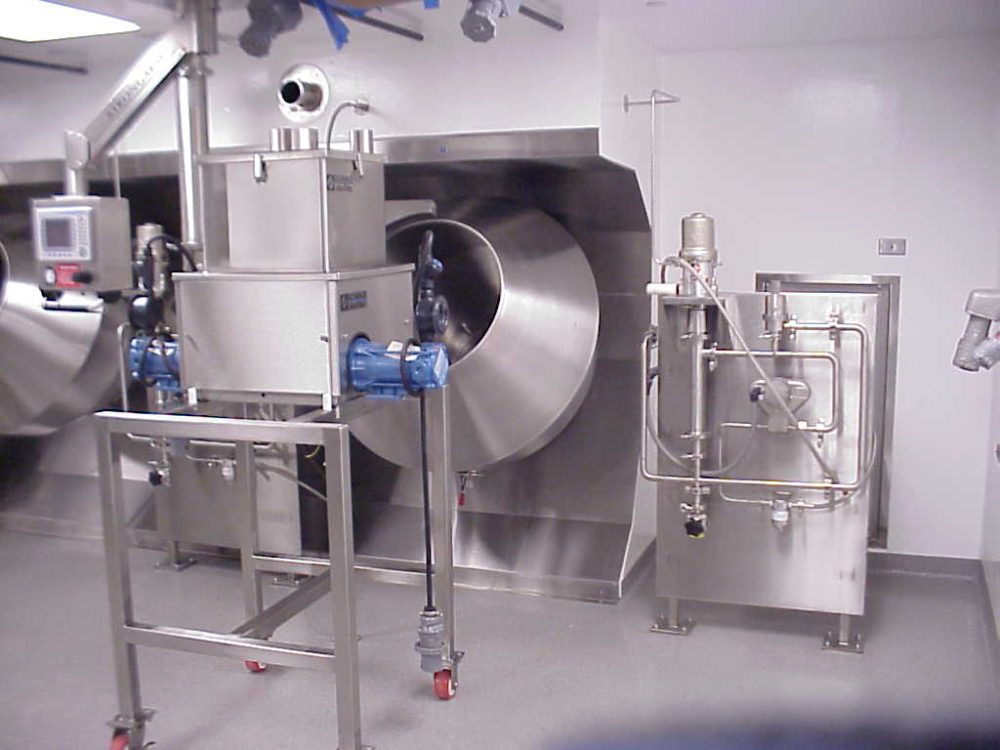

Ceramic manufacturing is the procedure of shaping and shooting ceramic materials to develop items. Ceramics can be made from clay, glass, metal, or synthetic products. Laser reducing can be utilized in the ceramic production process to produce precise forms as well as designs in the material. This sort of cutting is commonly used to produce intricate patterns and also decorative aspects in items.The type of laser cutting used in the ceramic market is commonly carbon dioxide laser cutting, which uses a high-powered laser to puncture the product. This kind of laser cutting is exact and also can develop really complicated styles. Carbon dioxide laser cutting is additionally relatively quickly, making it perfect for use in the ceramic manufacturing process.

Silicon making describes the manufacturing of silicon wafersthin discs of semiconductor product that are used in the construction of different electronic devices. The kind of laser cutting used in this market is understood as carbon dioxide laser cutting. It is made use of to produce the small-scale functions found on silicon wafers.

Everything about Durma Fiber Laser

These items can be utilized in a selection of industries, such as building and construction, automotive, as well as aerospace. The woodworking industry is a market of the production sector that produces timber items. These products can be made use of for building, furnishings production, or various other purposes. Laser-cutting technology is typically used in this sector to produce precise and elaborate designs in wood.

This kind of laser utilizes a beam of infrared light to cut through wood. Figure 1 is an example of laser reducing with wood:.

The Single Strategy To Use For Durma Equipment Toronto

Water is a regularly utilized coolant, usually distributed through a warmth transfer or refrigerator system. One instance of water cooled laser processing is a laser microjet system, which combines a pulsed laser light beam with a low-pressure water jet to lead the beam of light similarly as an optical fiber.

Fiber lasers are additionally acquiring appeal in the metal cutting industry. This technology utilizes a strong gain medium instead of a liquid or gas. The laser is intensified in a glass fiber to create a much smaller place dimension than that attained with CO2 methods, making it suitable for reducing reflective steels.

Our Laser Cutting Toronto Ideas

Plasma cutting which is a thermal cutting method, is widely used to reduce or etch on products such as metals. This is among the fastest cutting techniques readily available that ensures top quality and precise cuts without causing any deterioration on the material. Although being a prominent steel reducing method, the majority of us are not aware of plasma cutting.As a result, plasma cutters can pass through steels such as brass, light weight aluminum, steel, and copper with no resistance. A Plasma Reducing Maker operates by utilizing ionized gas (plasma) to puncture conductive products. It involves a power supply, gas flow, plasma generation, a plasma torch, and also the cutting procedure (Laser cutting toronto).

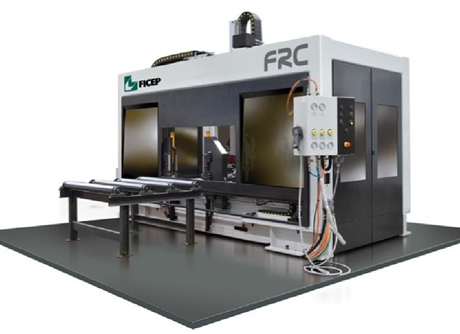

The business is a leading service provider of sheet steel fabrication devices and also equipment.

The Ultimate Guide To Durma Press Brakes Toronto

Main goal of production is to transform raw or scrap product to beneficial item. There exist different kinds of making procedures to satisfy such need. Sometime the raw or scrap material is melted and also put into a premade tooth cavity to obtain that impact and this process is referred to as casting.In forming, raw product is created right into a certain form according to the demand by using exterior pressure. All these procedures specifically casting, forming and also joining are generally one type of making process. Machining is one more such example where product is gotten rid of from the job by cutting (shearing) to acquire desired item.

By the means, bulk of design applications are based upon steels, so the alternative name is quite rewarding. Conventional machining procedure is schematically shown in above number. The figure is made use of Orthogonal Aircraft, and also hence the suffix 'O'. It needs to be kept in mind that the uncut chip density (a1) is constantly lower than chip density (a2).

Getting My Durma Press Brakes Toronto To Work

Therefore machining is likewise called a Subtractive Manufacturing Refine. On the other hand, rapid prototyping is one sort of Additive Manufacturing Refine. Learn more: Additive and subtractive production procedures. Machining is not just relevant for 'Metals', instead any kind of product can be machined. Metal is one view publisher site type of material, the various other 2 are Polymer as well as Ceramic.Remember, in machining, product is primarily gotten rid of by shearing. The cutting tool presses the material ahead it, there exists no pure compressive or tensile activity in elimination of chip. Chip removal is assumed as a shearing procedure. The phrase "pre-formed space" has unique relevance in machining. The term "blank" basically shows the workpiece or work that needs to be machined by any kind of kind of machining operation.

Because of this, plasma cutters can travel through steels such as brass, aluminum, steel, and also copper without any resistance. A Plasma Reducing Device runs by using ionized gas (plasma) to cut with conductive products. It includes a power supply, gas circulation, plasma generation, a plasma lantern, as well as the cutting process.

The 8-Minute Rule for Laser Cutting Toronto

The firm is a leading company of sheet metal fabrication devices as well as devices.

In forming, resources is developed into a certain shape based on the requirement by using exterior pressure. All these processes particularly casting, creating and also joining are generally one sort of manufacturing procedure. Machining is another such instance where material is gotten rid of from the work by cutting (shearing) to acquire desired things.

Some Known Factual Statements About Plasma Cutting Toronto

By the way, bulk of design applications are based on metals, so the alternate name is fairly enjoyable. Standard machining process is schematically shown in above number.Thus machining is also called a Subtractive Manufacturing Process. In contrast, quick prototyping is one kind of Additive Production Process. Review a lot more: Additive and also subtractive production procedures. Machining is not only relevant for 'Metals', rather any kind of product can be machined. Steel is one kind of material, the various other two are Polymer and also Ceramic.

Remember, in machining, material is essentially gotten rid of by shearing. The reducing device you can look here presses the material ahead it, there exists no pure compressive or tensile activity in removal of chip.

Report this wiki page